Introduction to CNC Turning

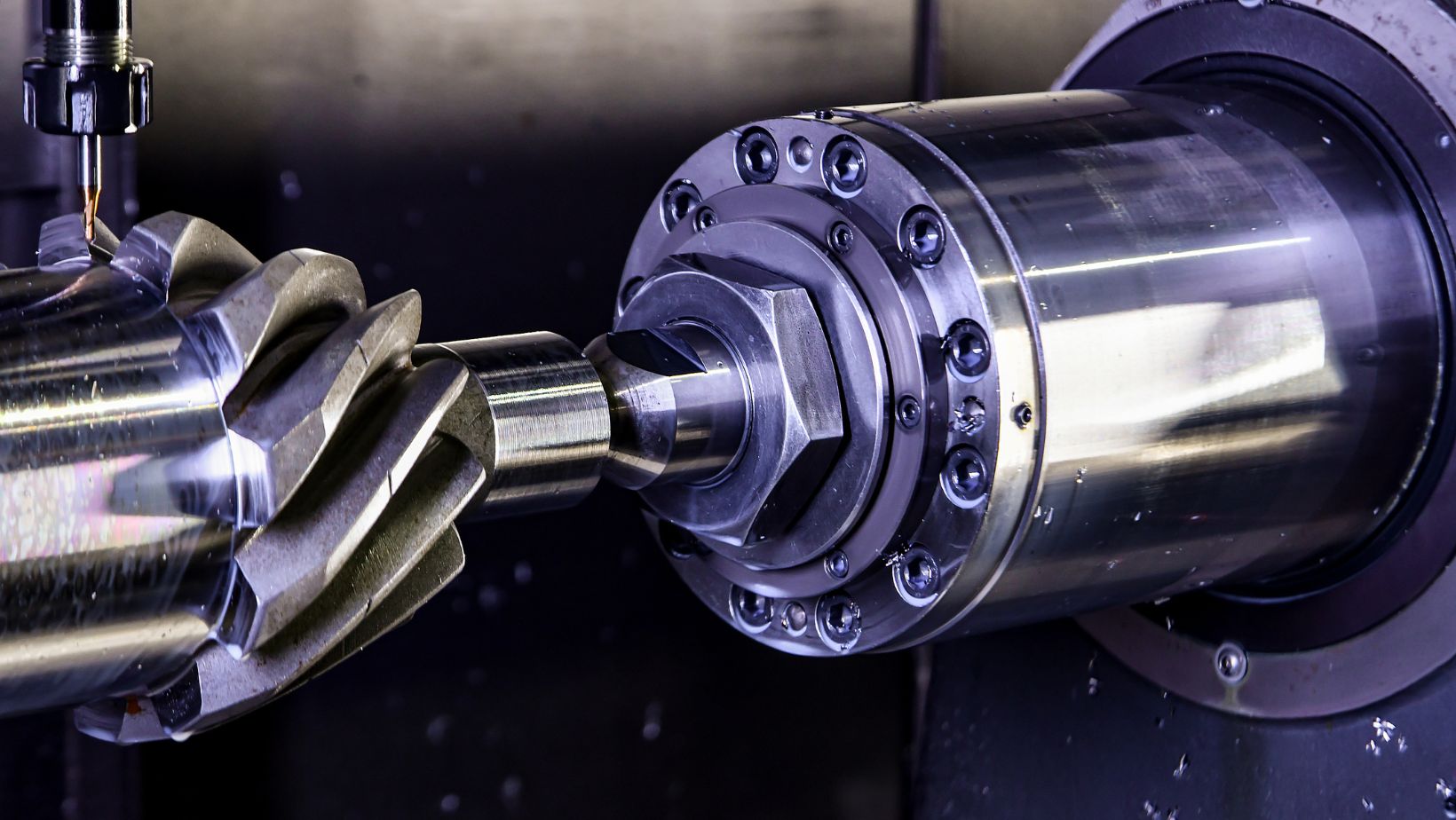

In the fast-paced manufacturing world, CNC Turning stands out as a transformative process that has redefined production standards. As a method that primarily focuses on machining cylindrical components, CNC Turning utilizes advanced computer numerical control to manage the automation of lathes and mills. This technology integration enables precise crafting of detailed components, significantly reducing human error and enhancing overall product quality. This technological leap has been crucial for industries like automotive, aerospace, and medical devices, where precision and efficiency are paramount.

CNC Turning is not just about making cuts; it’s about transforming complex digital designs into precise physical objects with minimal human intervention. Manufacturers can create intricate designs that are replicated flawlessly by utilizing sophisticated CAD systems. This capability allows for product design and engineering innovation, boosting the manufacturing sector’s ability to meet evolving market demands with precision and reliability.

Increased Precision and Accuracy

The accuracy and precision offered by CNC Turning are unmatched, rendering it a vital instrument for sectors where even the most minor details matter. By converting CAD designs into physical components, CNC Turning ensures that even the most intricate parts are accurately manufactured, maintaining tolerances that satisfy stringent industry requirements. This is particularly beneficial for sectors like aerospace and electronics, where every component must meet exact specifications to ensure overall system integrity and safety.

This degree of precision means reduced need for manual quality checks and modifications, streamlining the production process and allowing for faster throughput. It translates into significant savings in time and resources, providing a competitive advantage to companies adopting this technology.

Cost-Effectiveness Over Time

Although the initial investment for CNC machines can be high, the resulting efficiencies significantly mitigate these costs over time. The precision of CNC Turning reduces material waste by optimizing cutting paths and material usage. This efficiency significantly diminishes waste, guaranteeing that a greater quantity of raw material is included in the final product. As highlighted in American Machinist, material selection plays a critical role in maximizing these efficiencies, further enhancing the cost-effectiveness of CNC operations by minimizing tool wear and machining time. Additionally, once programmed, CNC machines can operate with minimal supervision, reducing the need for large skilled labor teams. This shift allows companies to lower operating expenses and reallocate workforce resources to more strategic areas, such as process improvement and quality control. The cumulative savings from material, labor, and error reduction contribute significantly to the cost-effectiveness of CNC Turning over the lifecycle of the production equipment.

Enhanced Production Speed

In our fast-paced market landscape, speed is often synonymous with success. CNC Turning greatly enhances production speed, enabling manufacturers to meet and exceed their production goals. Its automation capability ensures that machines run continuously with minimal downtime, dramatically increasing output without sacrificing quality. As highlighted in The Boss Magazine, CNC machining significantly reduces manufacturing lead times, serving as a critical resource for companies aiming to stay competitive in their sectors. This heightened production capability allows quicker turnaround times on orders, effectively positioning manufacturers to meet tight deadlines and maintain competitive relevance. The ability to swiftly pivot production lines to new projects or designs can also capture additional market opportunities, further driving business growth.

Consistent Quality for Large Production Runs

CNC Turning offers a critical advantage in delivering consistent quality for manufacturers committed to producing large quantities of uniform products. Every component manufactured through this process can replicate the exact specifications of the original design, ensuring uniformity in massive production runs.

This consistency is vital in industries where uniform component performance is crucial, such as automotive manufacturing or consumer electronics. Eliminating variability in production not only enhances product reliability but also significantly reduces deviation-related issues, lowering the potential for costly recalls or customer dissatisfaction.

Versatility in Material Usage

CNC Turning’s adaptability to various materials—from malleable metals to resilient plastics—marks it as a highly versatile manufacturing tool. This flexibility allows manufacturers to diversify their production capabilities and handle various projects and materials.

The ability to pivot between different materials without needing extensive equipment changes makes CNC a favored option for manufacturing firms seeking to respond swiftly to market demands or prototype new products. This versatility fosters innovation, enabling manufacturers to explore new applications and markets with minimal upfront risk and cost.

Conclusion

Ultimately, CNC Turning offers numerous strategic advantages for manufacturers aiming to improve their operations’ precision, efficiency, and cost-effectiveness. Its ability to deliver consistently high-quality products with rapid turnaround times supports ongoing business success in competitive markets. As industries evolve and demand greater efficiency and accuracy, CNC Turning is a cornerstone of progressive manufacturing, providing the expertise and capability needed to meet and exceed industry expectations.