If you’re involved in modern manufacturing, you’ve likely noticed an increasing emphasis on sustainability and efficiency. Have you ever considered how robotics, intertwined with artificial intelligence (AI), is driving this transformation?

In this article, we’ll explain how smart factories are using these technologies to pioneer sustainable manufacturing practices that could redefine your industry.

The Emergence of Smart Factories

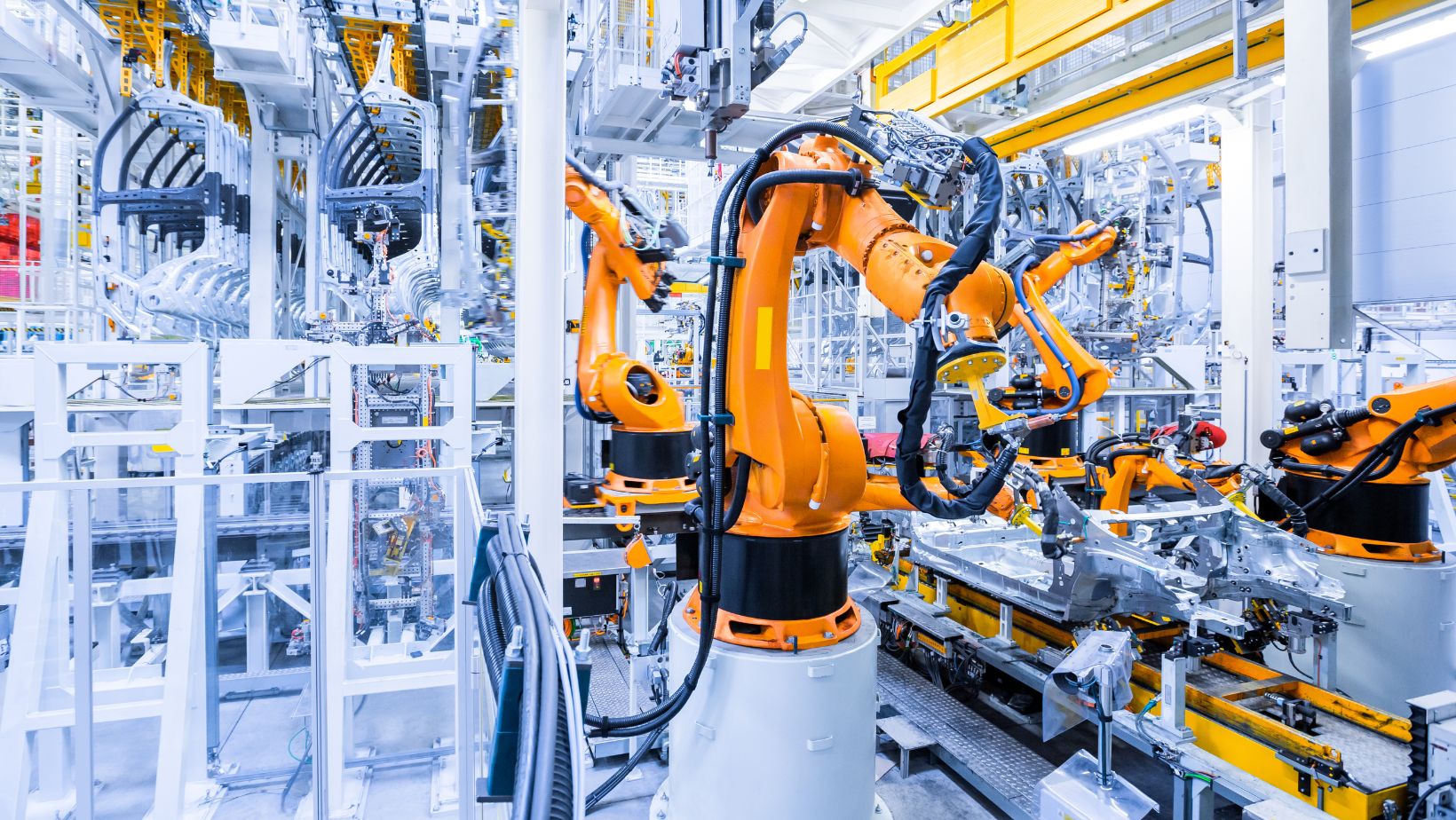

Smart factories represent the pinnacle of industrial evolution, with robotics and AI at their core, creating an environment where machines and systems communicate seamlessly to optimize production processes.

In these factories, every element of the manufacturing process is monitored and adjusted in real time, minimizing waste and energy use. When you ask about “robot pricing,” you’re touching on a critical aspect of why smart factories are becoming more accessible and prevalent. The cost of robotics has been decreasing due to advancements in technology and increased production scales. This makes it feasible for even small to medium enterprises to invest in robotics, enabling them to compete on new fronts in efficiency and sustainability.

Integrating Robotics with Artificial Intelligence

Imagine robots in your factory that perform tasks, learn, and adapt. This is where AI comes into play. AI algorithms can analyze data from robotic operations to improve efficiency and adapt to new production methods without human intervention.

This capability allows you to reduce downtime and predict maintenance needs, significantly lowering the risk of costly disruptions.

Artificial intelligence also enhances robots’ capability to handle complex tasks that require precision and variability, such as assembling intricate electronics. These robots can adjust their operations in real time, reacting to minute changes in component placement or assembly instructions, ensuring high quality while maintaining rapid production speeds.

Sustainability Through Advanced Robotics

Sustainability is no longer just a buzzword but a crucial aspect of modern manufacturing strategies. Robots, particularly AI-powered, play a significant role in making manufacturing processes more sustainable.

For example, robots can optimize material usage, dramatically reducing waste. They can also operate in environments that may be unsafe for humans, such as high temperatures or toxic atmospheres, reducing health risks and enhancing workplace safety.

Moreover, the precision of AI-driven robots ensures that resources are used efficiently, leading to less material waste and energy consumption. This helps reduce the environmental footprint of manufacturing operations and cuts down costs associated with waste management and energy use.

Cost-Effectiveness of Robotic Solutions

One of the primary concerns when integrating new technology is the cost involved. With robot pricing becoming more competitive, the return on investment for robotic systems is more appealing than ever.

Smart factories utilizing AI-driven robots can achieve a level of precision and efficiency that significantly lowers production costs in the long run.

The deployment of robots in manufacturing also opens up opportunities for utilizing high-performance materials that might otherwise be too challenging or costly to work with manually.

Robots can handle these materials effectively, allowing for innovation in product design and functionality that can differentiate your products in the market.

Pioneering a Future with Smart Factories

In wrapping up, the role of robotics and AI in manufacturing is not just transformative; it’s revolutionary. As you make your operations more sustainable and efficient, consider how smart factories equipped with advanced robotics and AI can lead the way. Integrating these technologies supports environmental goals and enhances profitability and productivity.

Ultimately, AI will become much more accessible and AI technology will continue to advance. Thus, your opportunity to adopt sustainable manufacturing practices will grow. Those who leverage these technologies will save on costs, and completely transform their manufacturing abilities, outputs, and much more.